Eliminate production stops to meet tight margins and stay profitable

At first, we carefully go through the specifications of our industrial automation customers to find the most suitable solution. We want to understand the products, the weight, cycle times, and fluids involved in the different operations. We are familiar with the industry. We know how the different processes work and what type of machines are used in the production line. To deliver effective and well-functioning solutions required in the automotive industry, a comprehensive understanding of the industry and its needs is fundamental.

If you are looking for the right automation solution for the automotive industry, you might consider several factors. Evaluate the production machines and their operations carefully to balance the production line and avoid bottlenecks. At FlexLink, we have specialists to assist you on all stages of the evaluation process.

Some questions of a typical evaluation process

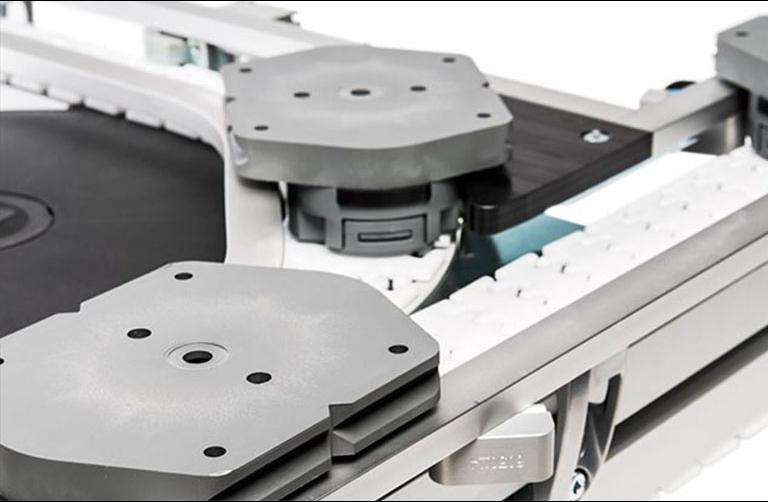

- Are pallets required, or should the products be placed directly on the conveyor track?

- How should the machines be placed in the factory plant to facilitate the product flow and ensure accessibility and productivity?

- What information do you want to obtain from the systems, products and processes?