Customized conveyor systems for the tissue industry

Typical for the tissue industry as a whole are the high-volume production flows. Products are usually manufactured in significant volumes. This requires effective production processes with high levels of automation. Additionally, there is tough competition between the different companies manufacturing products within the tissue industry. Manufacturers have their own brands, which have to compete with the retailers’ labels.

To help our customers meet these requirements, FlexLink has a wide range of solutions specifically designed for the tissue industry. This includes conveyor equipment and dynamic handling and distribution solutions that deliver high output and smart, compact layouts that enhance overall efficiency.

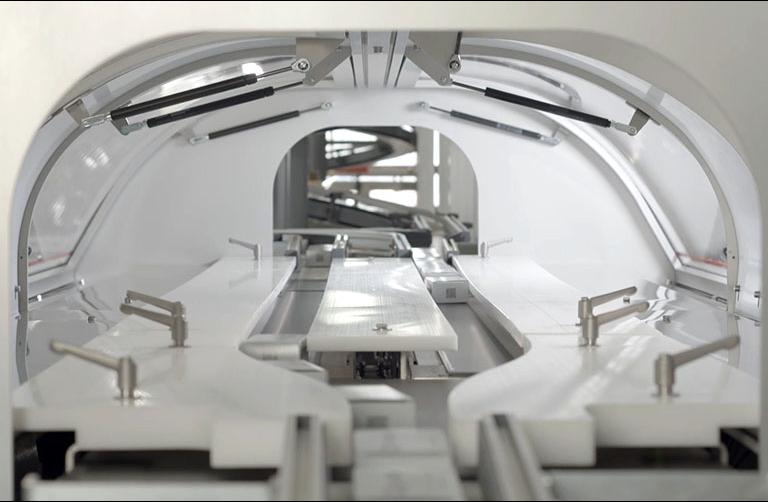

One example is the X65Y conveyor made for naked tissue in dusty environments. It offers high performance in terms of speed, length, and cleanliness, yet with a low noise level, long service life, and low maintenance costs.