Single track pallet systems for efficient product handling

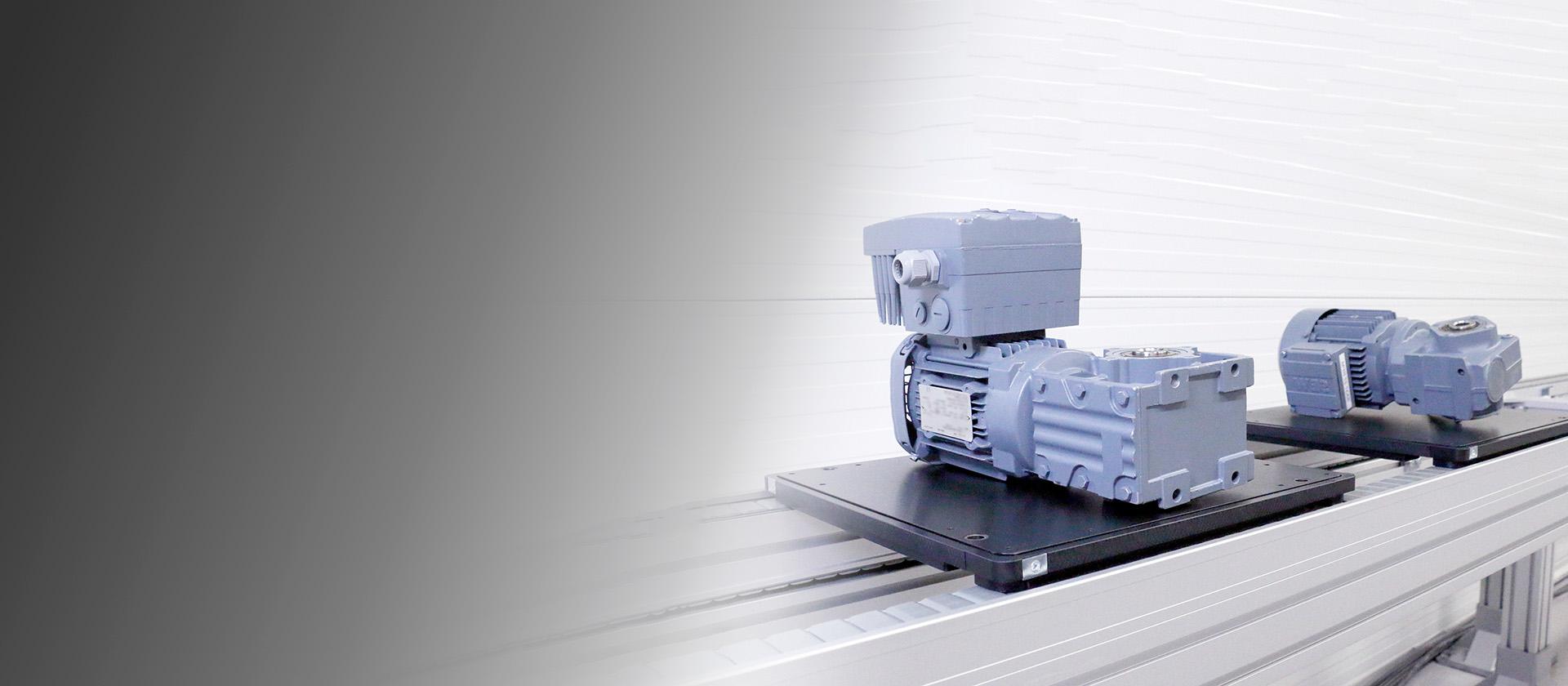

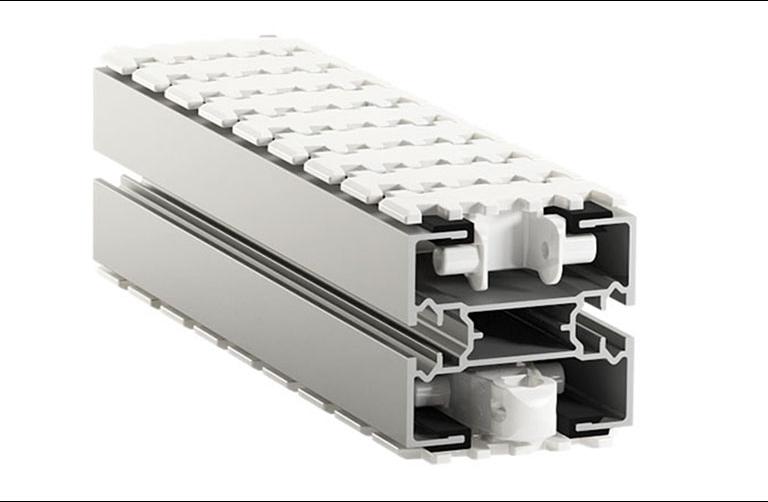

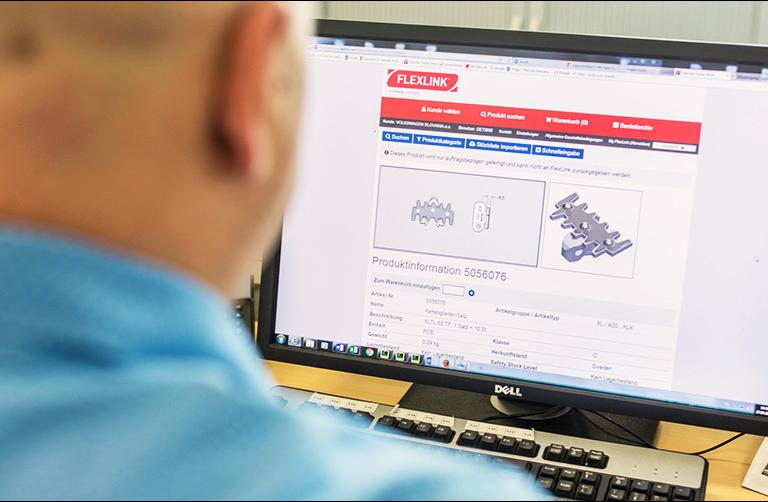

A pallet-based, single-piece flow solution from FlexLink helps you increase the sellable throughput of high-value products by individual product control. RFID identification in the pallets enables one-piece track-and-trace and production control of the line. Altogether, we offer a predictable process for a continuous flow with high throughput.

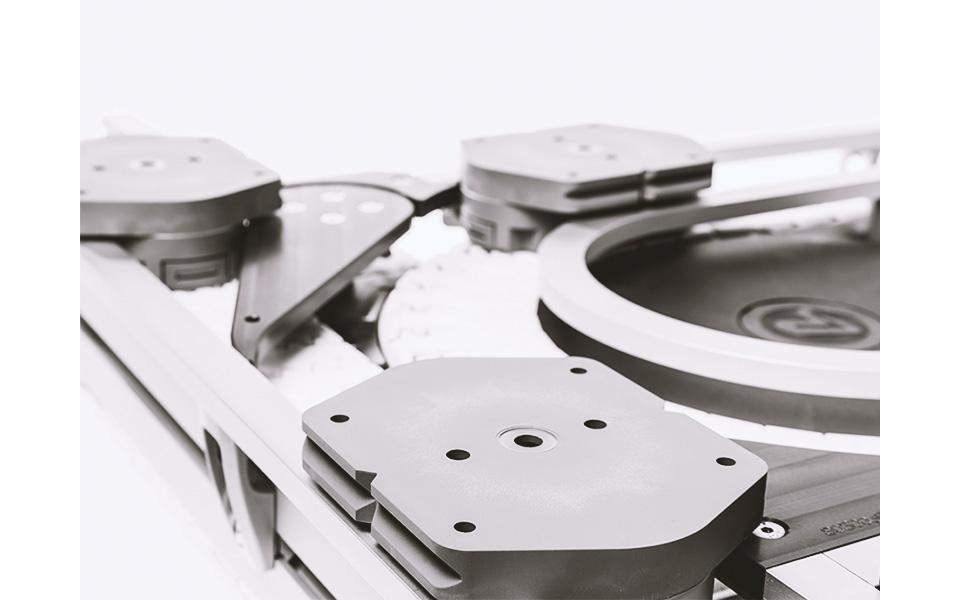

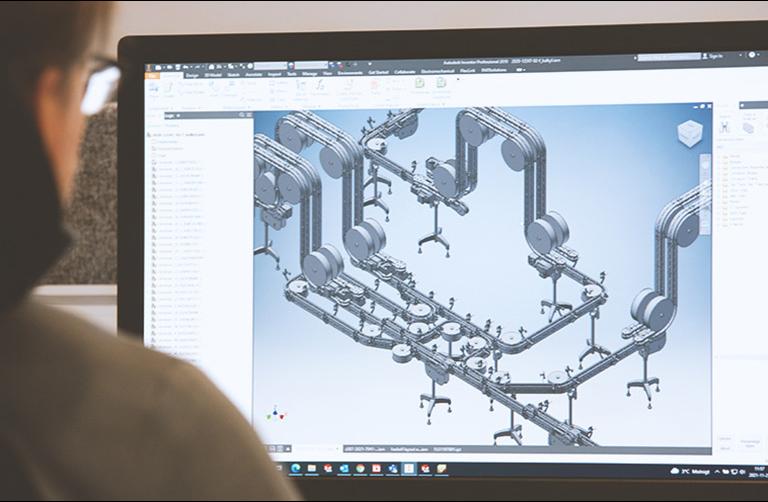

The FlexLink single-track pallet handling will support you with flow solutions that suit products of different sizes. We adapt our systems individually for each environment’s specific requirements, from small test objects on low weight on a pallet of 100x128mm(X65P) to larger products on a 300x300mm(XKP) pallet that can handle up to 30kg.

Since the system is based on the standard chain conveyor, all the benefits of the modular platform apply. In addition to that, pallet-specific functions, like pallet locating stations, pallet stops, pallet merge and pallet divert stations.