End-of-line optimization with automated palletizing

Our turn-key robotic solutions have two pallet positions for continuous workflow. They are best suited for palletizing cartons, trays, bags, or individual products.

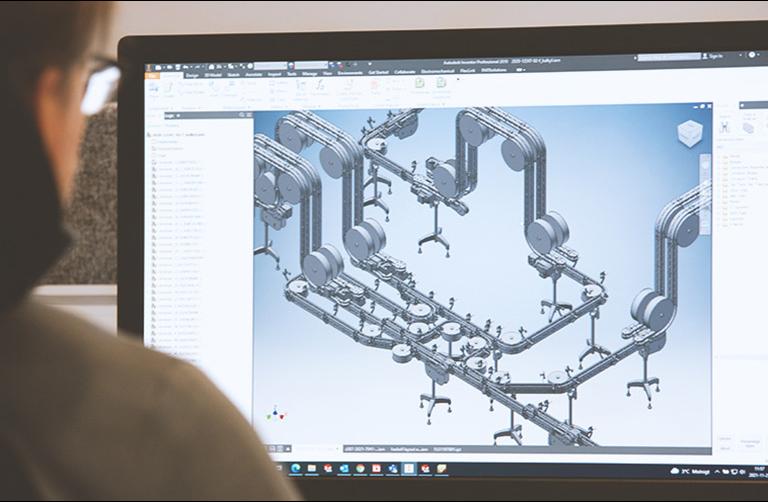

Highest mobility and easy configuration allow the use of our palletizers in all industries. The compact design ensures maximum flexibility and good process integration when using palletizers in your production.

Our palletizing robots guarantee smooth automation of industrial processes. They can also take over products directly from an Automated Guided Vehicle (AGV). The simple design, user-friendly initial startup, and intuitive operation of the easy-to-use control system guarantee a stable and smooth automation process.

Automated palletizing with FlexLink palletizers reduces the workload of your employees. Using robotic palletizing solutions enables you to achieve effective and sustainable benefits by fully automating physically demanding and time-consuming tasks.