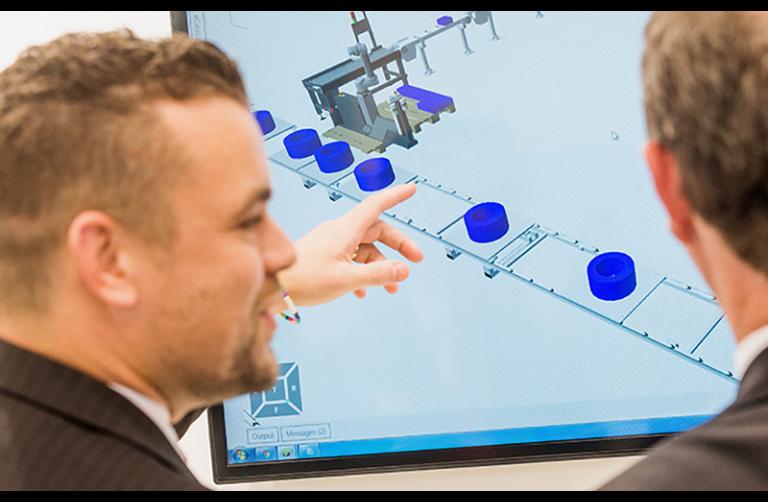

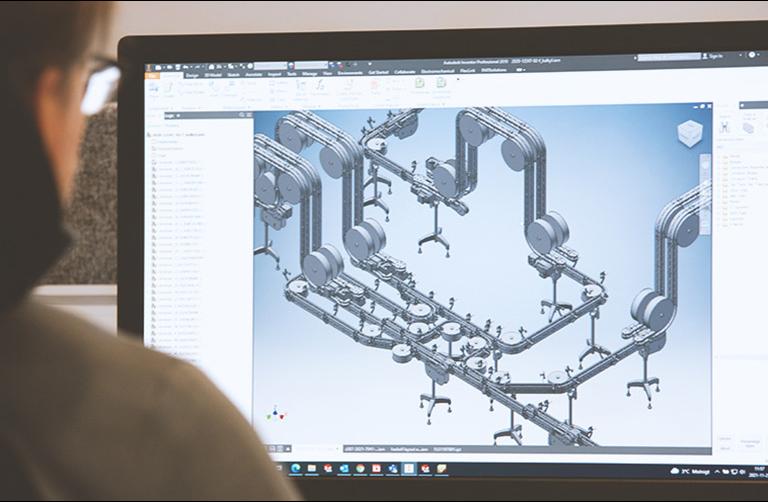

Equipment modernization

Are you planning on making changes or modernizations to your production line? The reasons for doing so can be many, e.g., to improve line efficiency, new product introductions, or increased production targets. We have over 40 years of experience in processes, system analysis, and line design to support your continuous improvement needs.