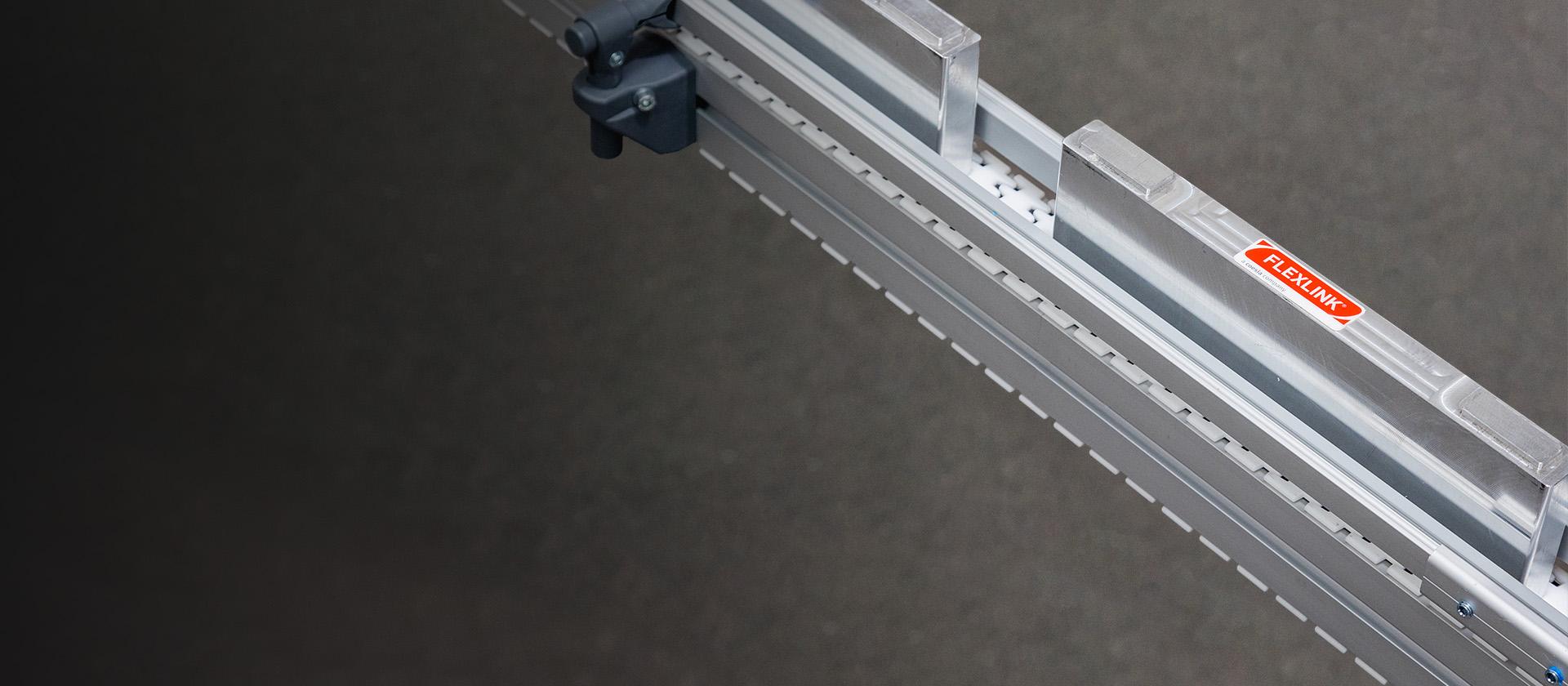

Production automation equipment for battery manufacturers

FlexLink is a leading manufacturer of conveyors and manufacturing automation equipment for EV battery manufacturers and other heavy battery production operations. FlexLink offers a wide range of battery manufacturing conveyors and electric vehicle components manufacturing equipment for:

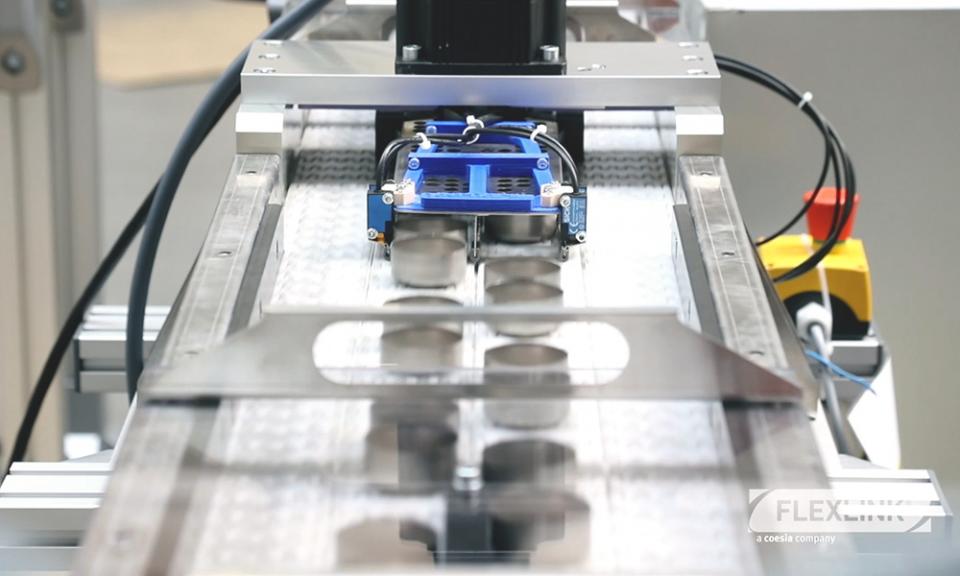

- battery cell handling

- battery case handling

- jelly roll and assembly process

- battery leakage test, aging, and curing

- battery activating and charging processes

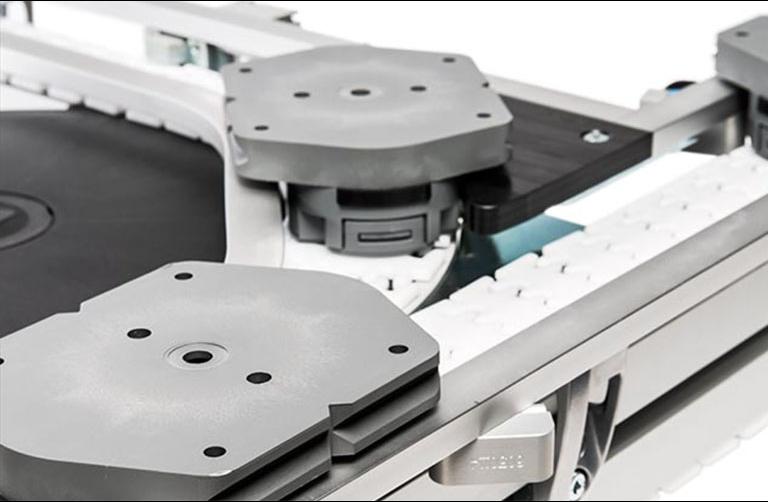

- battery module assembly

- battery logistics packing or module assembly

- inverter ac/dc converter manufacturing

- electric motor assembly

- handling other heavy products