Challenges for packing operations

Today, customers want more unique and personalized products, which leads to a greater variety of products needing to be made and delivered in various formats. This creates growing challenges for manufacturers, brand owners, and service providers involved in packaging, co-packing, storage, and transportation, especially during busy seasons.

Furthermore, the lack of resources and rising costs require new solutions to automate processes, free up employees, and boost efficiency.

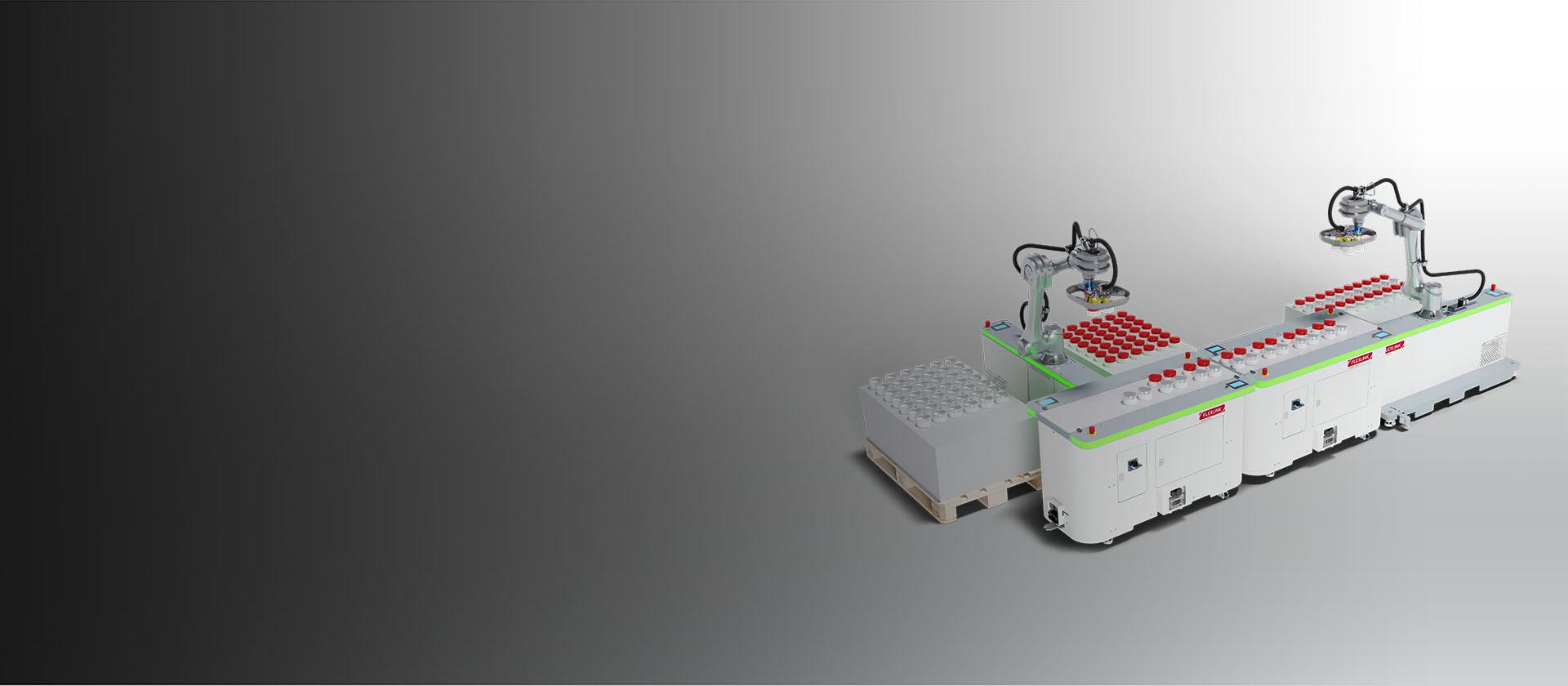

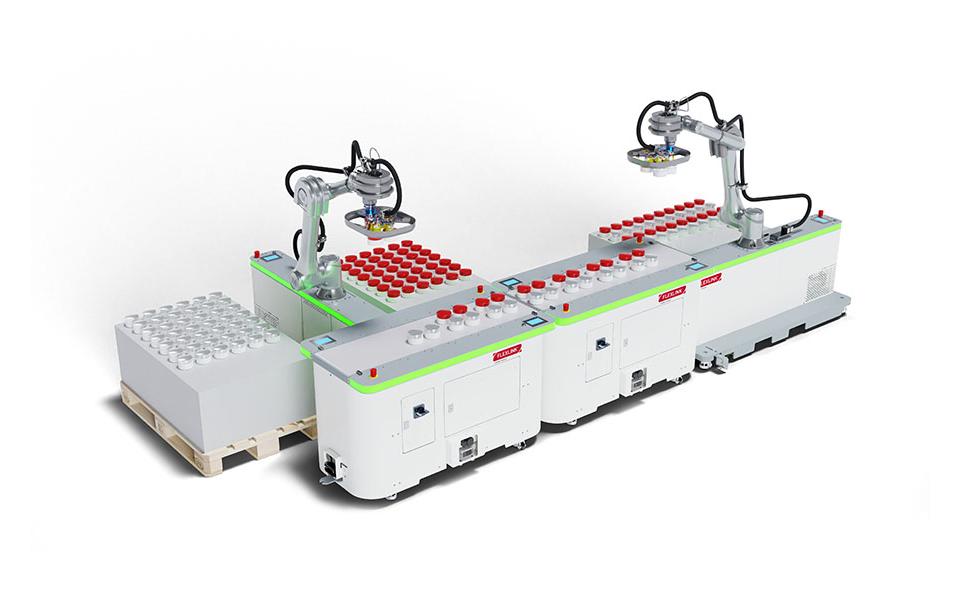

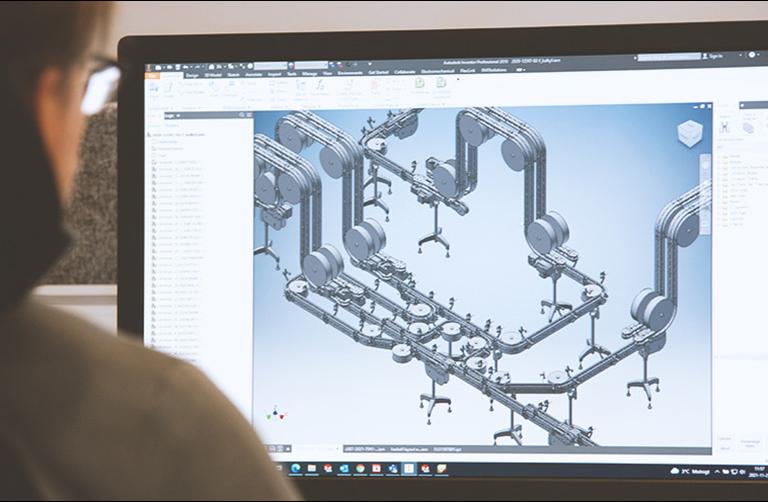

BRIXX® Applications

The versatile BRIXX® modules can perform a wide range of tasks using the same hardware and software. Production companies or co-packers can automate various product-related processes, such as picking and placing items, mixing, labeling, re-labeling, stacking on pallets, or removing from pallets, to enhance productivity and efficiency.

Additional processes, like forming cases, creating trays, and closing cartons, are also available as options.