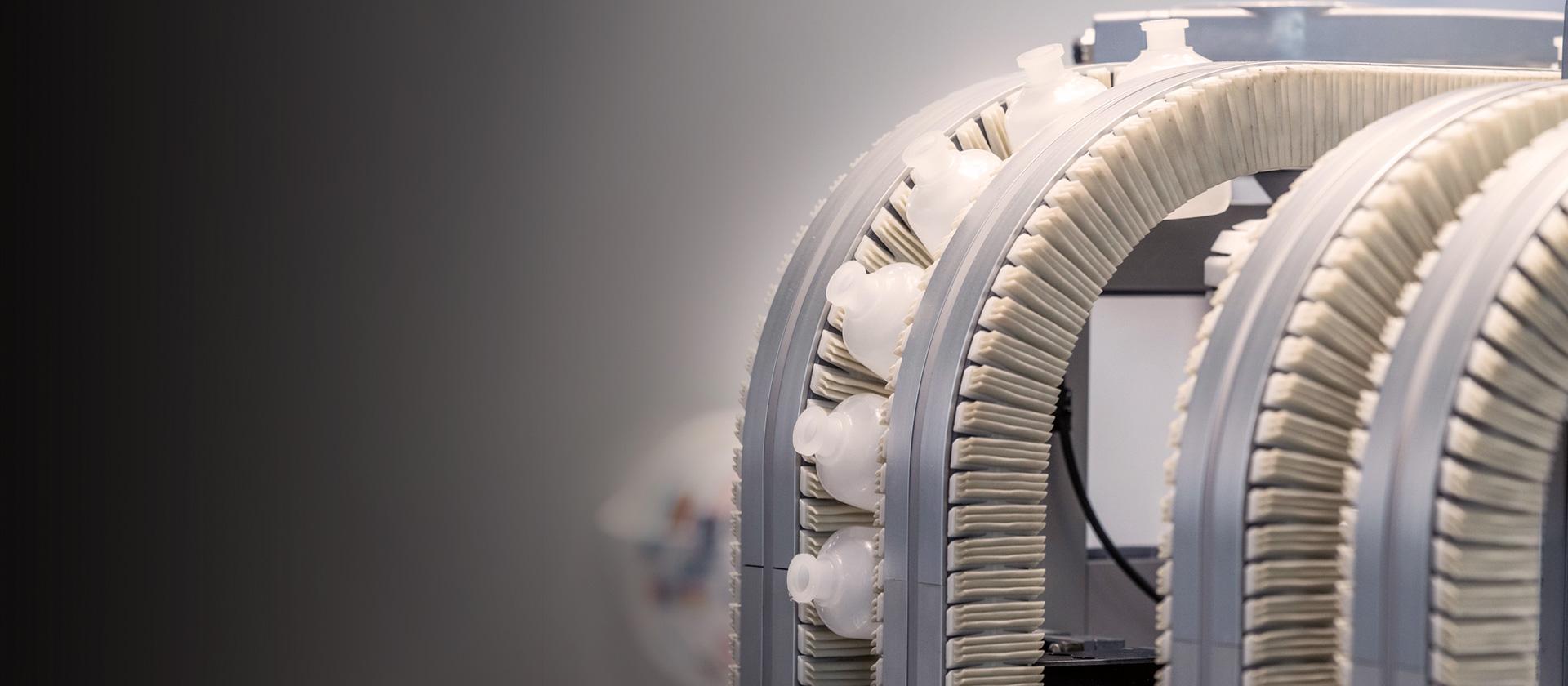

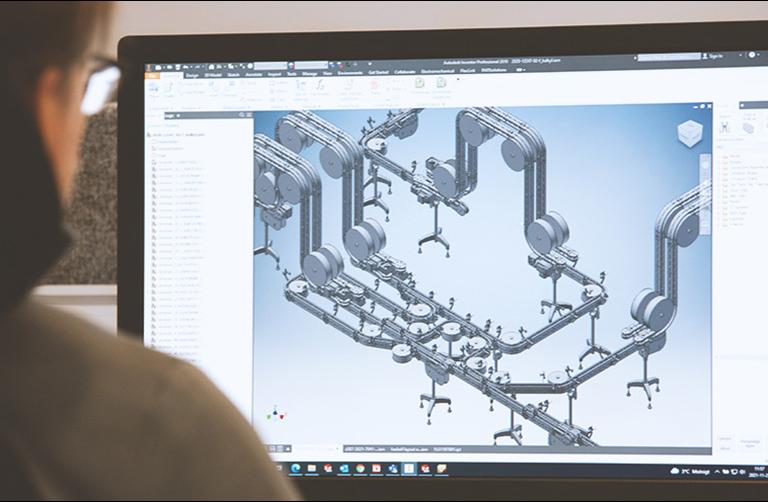

Flexible conveyor for vertical transport

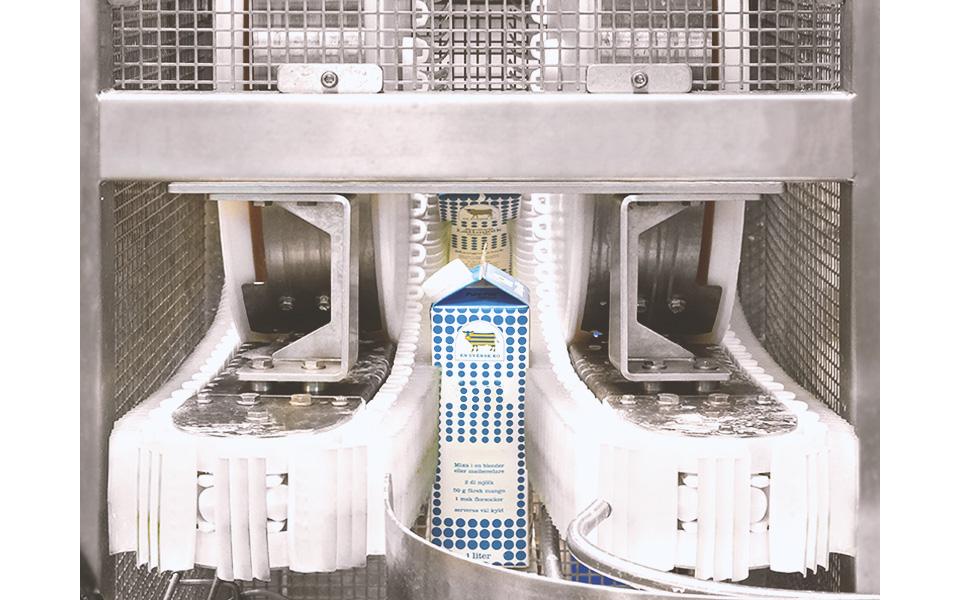

The wedge chain conveyor takes a product or package smoothly from one level to another at speeds of up to 50 meters per minute. Suitable applications include the transport of cans, glass, batteries, plastic bottles, cardboard boxes, tissue paper, and many others.

Important features

-

Fast, high-capacity vertical transport

-

Smooth handling of products

-

Suitable for filling and packaging lines, etc.

-

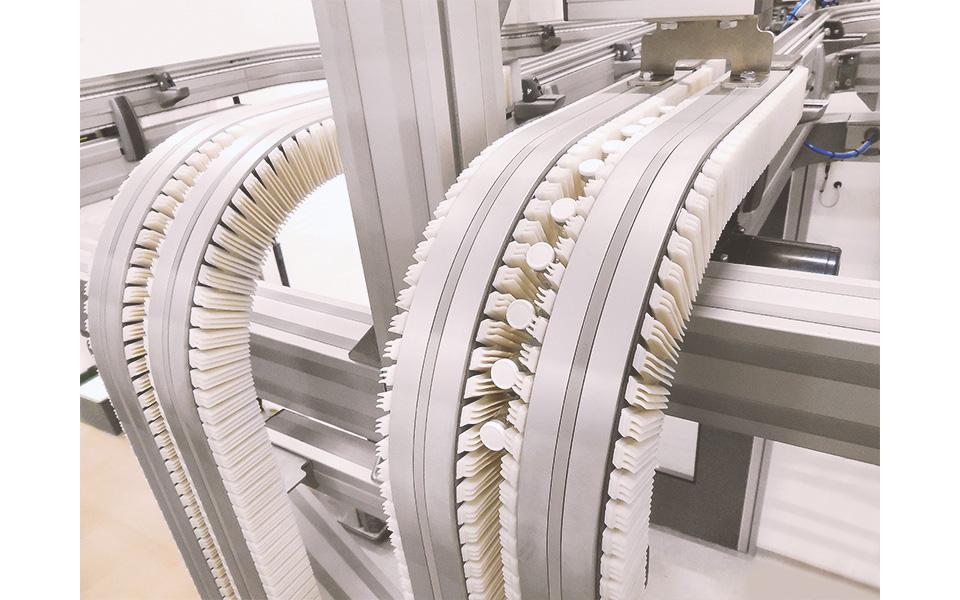

Flexible building block principle

-

Lightweight, space-saving system

-

Only hand tools required to build the conveyor

-

Easily integrated into other FlexLink conveyor systems

The sweet spot of a wedge conveyor

Due to their operating principle, wedge conveyors can lift smaller products higher than other solutions. In operation, a wedge conveyor applies some pressure to the sides of conveyed products that they need to withstand. This kind of transportation also prefers dry objects for optimal friction. Wet surfaces can cause slippage, slowing the flow of the products. Support rails allow even lifting of products that are heavier or susceptible to compression. Limiting factors for wedge conveyors are very heavy or irregularly shaped objects.

Use FlexLink’s expertise to find the right chain solution for your specific demands.