Description

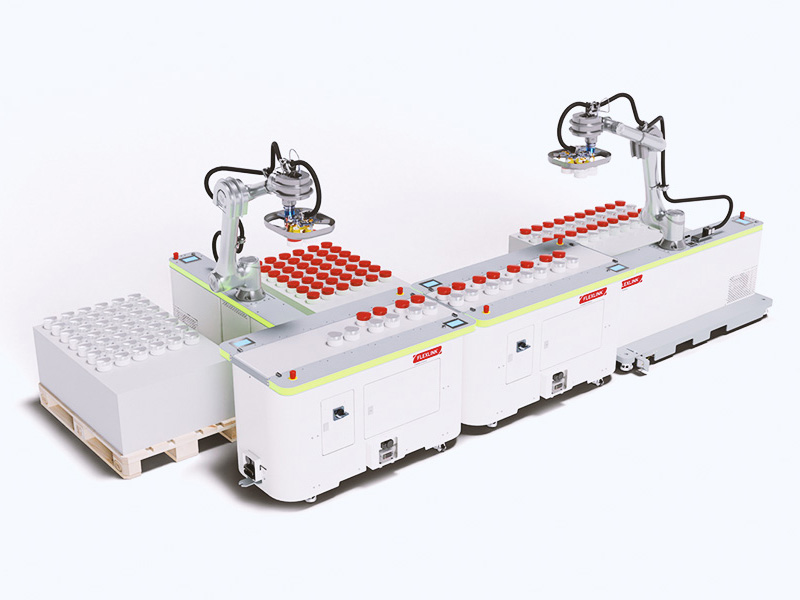

BRIXX® is a new, modular,

click-and-play solution based on an intuitive software to reduce the manual

operations and allow quick transformations for co-packing lines. Based on

advanced, mobile conveyors and robots to automate manual repetitive packing and

co-packing processes.

This

unique design by FlexLink is a solution to automate currently manual packing

operations through a flexible system adapting to the variability of products,

packs, cartons, or trays. It is scalable according to production capacity

needs, affordable and easy-to-use.

It is controlled by an

intuitive software for line design and operations, as well as fleet management

allowing to manage seasonal peak productions.

The flexible combination of BRIXX®

modules enables a wide range of operations with the same hardware and software.

Production companies or co-packers can automate product transformations such as

pick-and-place, mixing, labeling, re-labeling, palletizing or de-palletizing

for increased productivity and efficiency. More product transformations such as

case forming, tray forming, and carton closing are optionally available.

Marketing Documents:

• Learn more

about BRIXX®

• Need a

technical expert? Find your closest FlexLink office