Description

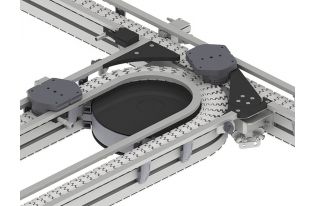

With the ability to handle payloads of up to 15kg at 12 cycles per

minute, the RI20 does not have a mainframe attached to the floor, making

it a mobile solution suitable for use in multiple production lines.

Robot set-up and configuration are straightforward, thanks to the

user-friendly design of the interface. Also available on a tablet, in addition

to the control panel, there is no need for complicated programming or robotics

training, meaning the RI20 facilitates quick and easy set-up. FlexLink also offers

a data collection package and a telephone helpline for remote assistance.

Two pallet loading positions enable continuous operations, and an

enhanced safety system creates a safe co-existence with operators. When motion

is detected in the safety area, the production does not stop. Instead, it slows

down. The movement is identified by scanners and light curtains, changing the

robot arm's speed.

- Learn more about the FlexLink Design Tool

- Explore how to order equipment directly in our Online Store

- Need a technical expert? Find your closest FlexLink office

Technical Documents:

RI20