Rapid time-to-market

FlexLink’s solutions are designed to quickly adapt to meet changes in demand and handle many product variants simultaneously, with minimum resetting time. Flexibility and modularity make adapting to production line changes easy, which significantly facilitates new product introductions, reducing time-to-market.

Maximum sellable throughput

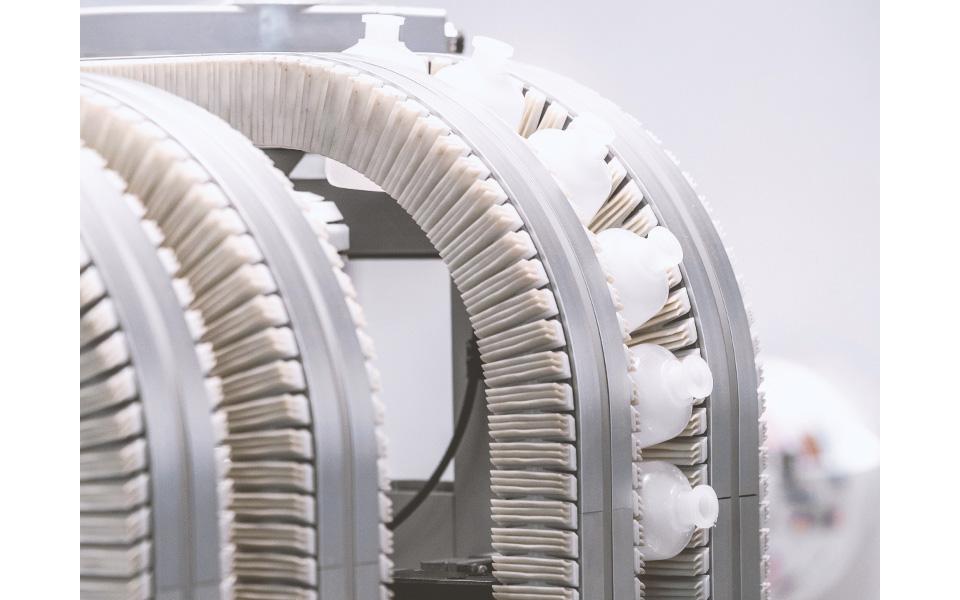

FlexLink’s solutions aim to achieve maximum sellable throughput. They can be used for all types of products, regardless of the size, shape, or fragility, handling them directly on the conveyor or using pucks and carriers. For example, FlexLink has solutions for moving empty bottles from the unscrambler onto a vacuum conveyor for filling, then along to a palletizer with case conveyors where shipping is carefully prepared. FlexLink provides tangible benefits by limiting damage to products and ensuring smooth transitions between machines for maximum uptime.