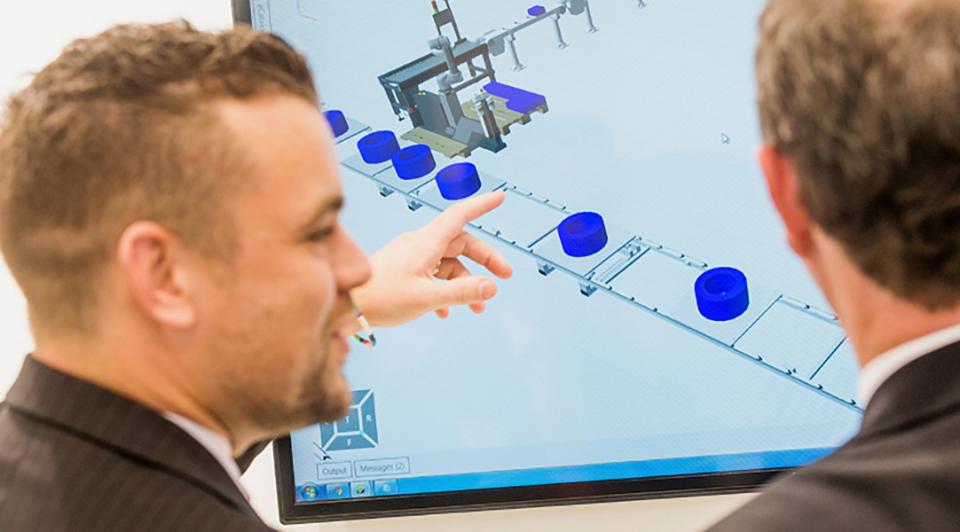

Test future production volumes and new product mixes

For a simulation to be accurate, the system's logic must be built according to a detailed specification defined by three different categories: system description, input data, and scenarios.

-

System description: defines the behavior of the system. It states how all processes interact and under what conditions they run.

-

Input data: E.g., order data, the delivery schedule for raw material, or cycle times. Input data and system description are enough to build a simulation model representing reality.

-

Scenarios: the simulation model is often built to test different scenarios and new product mixes. You can also do a wide variety of tests to see the effect on your production, e.g., what happens if a machine stops more frequently than expected or what happens if an operator can't reach a certain throughput.