Description

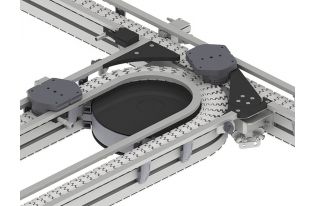

A collaborative robot palletizer, the RC12 handles payloads of up to 10kg at twelve boxes per minute. Without a fence or cage surrounding it, the small footprint gives flexibility in its location.

Following ISO standard TS 15066 for robots, the RC12 is designed to work alongside personnel; if an operator comes into contact with the robot arm, it will automatically stop to reduce the risk of injury.

Robot Config software allows the operator to quickly design a new pallet pattern or load an existing one, including interlayers and adjustments for label location. The drag-and-drop tool eliminates design errors and takes less than 10 minutes to create the first configuration. It eliminates the need for programming or training.

- Learn more about the FlexLink Design Tool

- Explore how to order equipment directly in our Online Store

- Need a technical expert? Find your closest FlexLink office

Technical Documents: