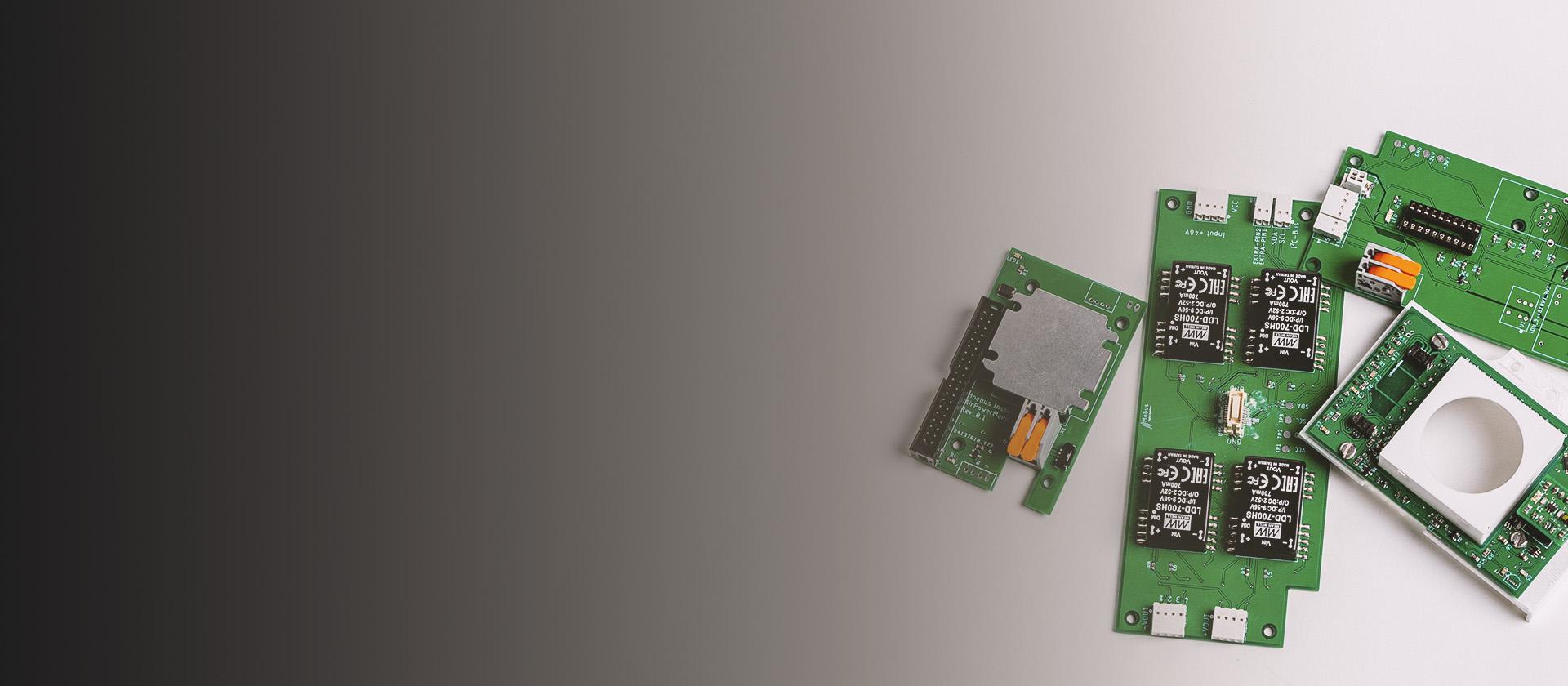

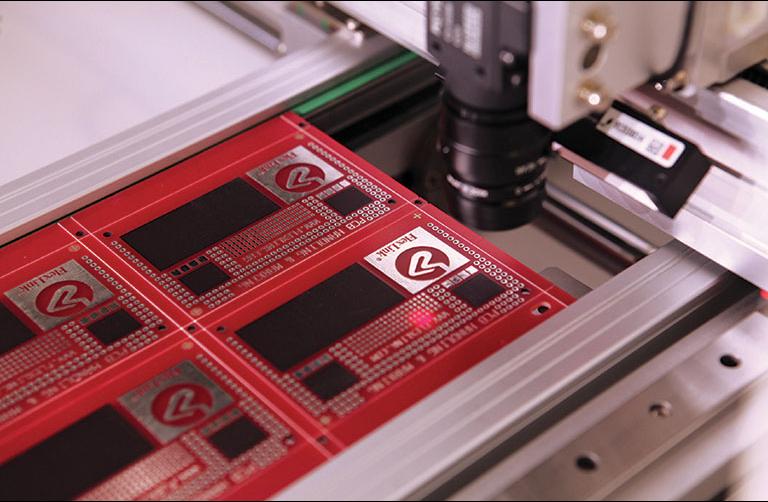

Versatile electronics industry automation solutions

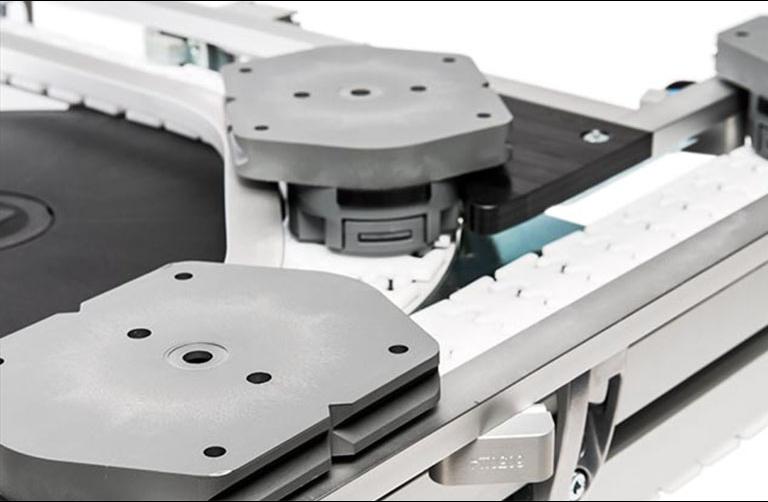

FlexLink has the product range to provide electronics industry automation solutions. From PCB handling and laser marking to pallet applications for manufacturing, assembly, and test. We make it easy to extend or modify your installations following changing production needs, keeping investment low. We do it fast, and we can assist you with step-by-step investments that follow product lifecycles.

Time-to-market and future modifications

FlexLink understands the customer's need for 'speed' from the first contact to implementing the final solution. Our high standardization levels enable us to respond quickly and keep us competitive throughout the process, from first response and proposals through project management, installation, commissioning, training, and after-sales support.