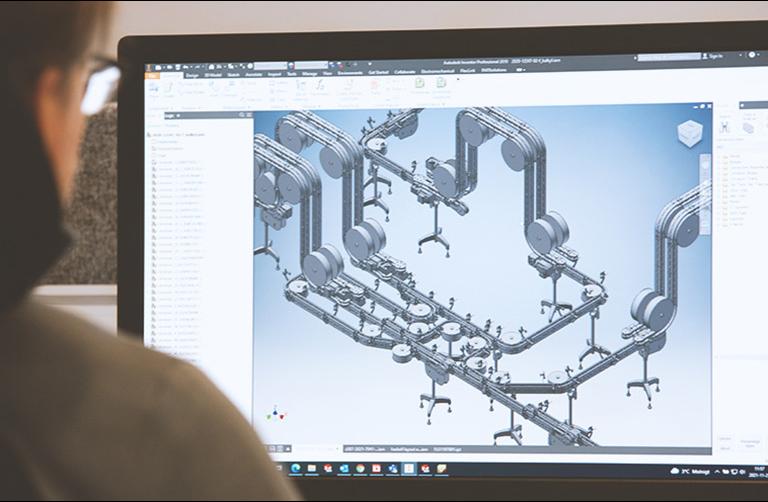

Elevating product handling

The purpose of the spiral elevator conveyor is to transport products vertically, bridging a difference of height. The spiral conveyor can lift the line to create space on the production floor or function as a buffer zone. The spiral-shaped conveyor is the key to its uniquely compact construction that saves valuable floor space.

Our spiral elevating solutions work perfectly in filling and packing lines. Possible applications of spiral elevators range from handling individual parcels or totes to items such as shrink-wrapped bottle packs or cartons.

Customer advantages

- Compact footprint

- Modular & standardized

- Gentle product handling

- Low noise level

- Different infeed and outfeed configurations

- Elevation up to 4 meters

- Different chain types and options