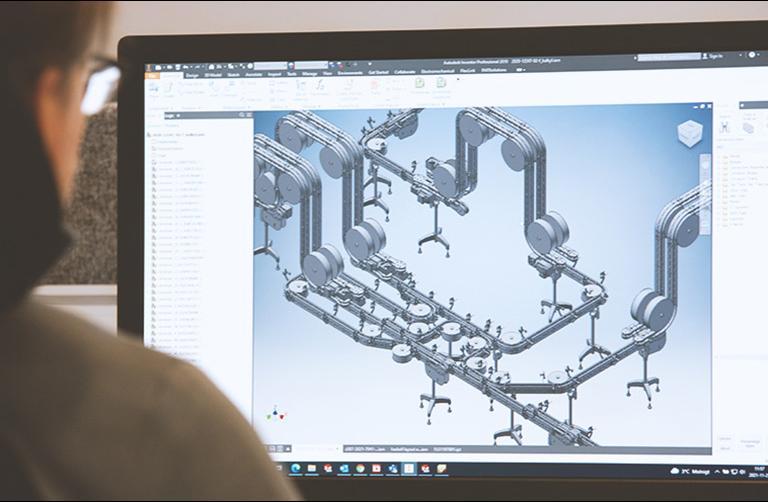

Fully modular stand-alone PCB handling units

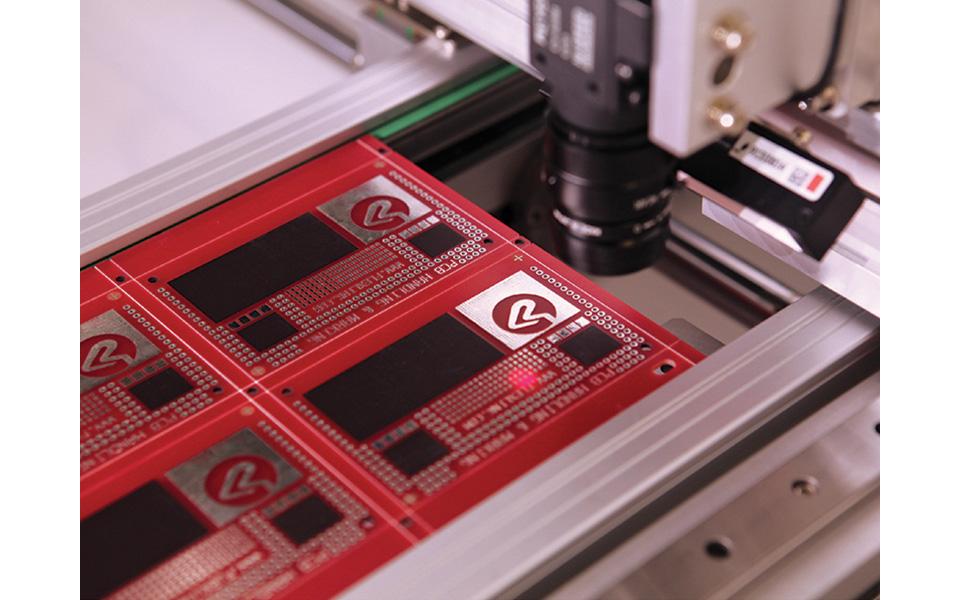

PCB handling product lines from FlexLink incorporate modular stand-alone units that are truly independent of other modules in the system.

Each unit has an onboard control system that allows it to function independently. The unit can be linked to others in the system by utilizing their upline and downline SMEMA communications. The modules can also link to a higher-level monitoring or routing system by utilizing a host control system. All units have ESD safe designs and are CE marked.

Range of PCB handling modules

- Single and multi magazine loaders and unloaders

- Stackers, restackers and destackers

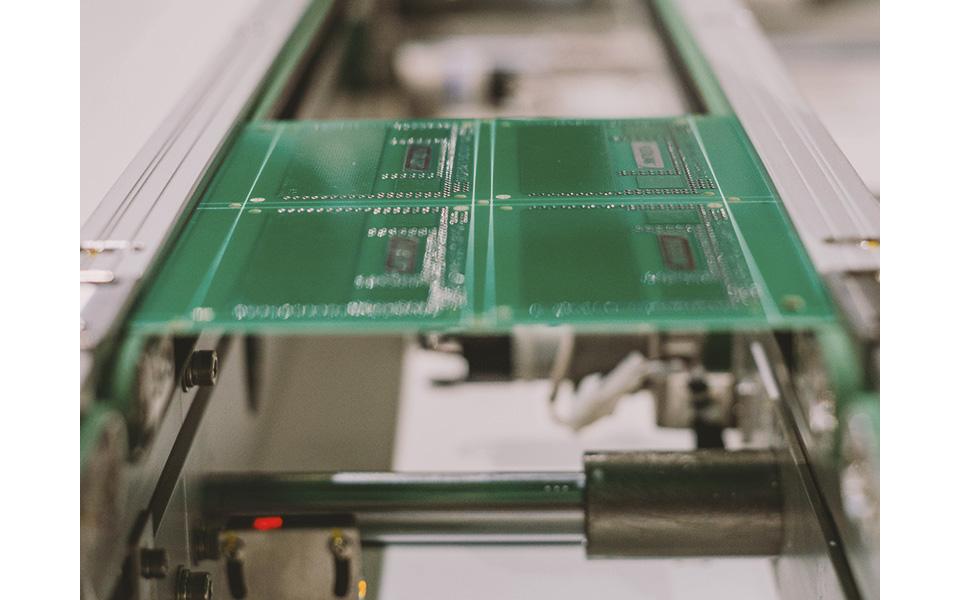

- Edge belt conveyors

- Inline workstations

- Reject conveyors with good/no good software

- FIFI and LIFO buffers

- Single and multi magazine buffer modules

- Liftgate conveyors

- Side shuttles and shuttle gates

- Turn units and inverters

- Elevators, chain conveyors and flat belt conveyors

- Laser markers

- Brush cleaners

- Backend assembly