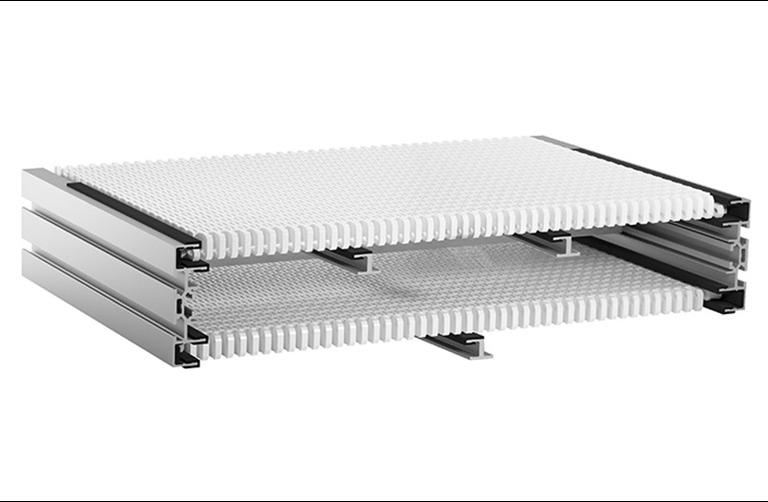

Modular wide belt conveyor for products that call for wide chains

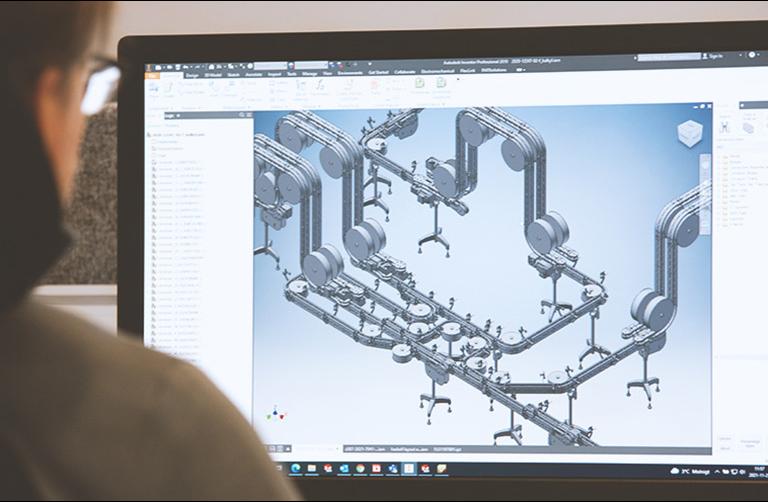

Modular wide belt conveyors are highly suitable for wide or bulky products requiring stable handling and to be kept in position even through curves. A typical area for plastic belt conveyors is the transport between case packers, cartoners, in-case fillers, shrink/stretch wrappers, or bulk packers. Here are some products that are usually handled with a wide belt conveyor:

- Secondary packaging of food and hygiene products

- Pouches

- Soft plastic bags

- Shrink-wrapped products

- Cardboard boxes

- Plastic containers

Primary and secondary packaging applications

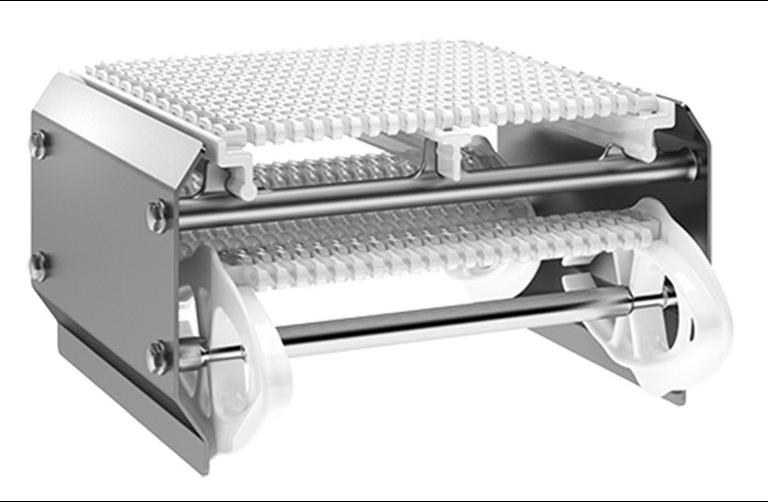

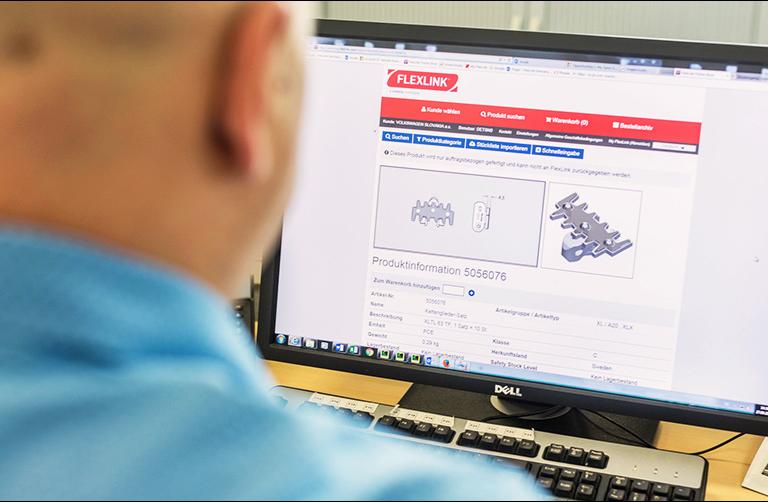

Our modular wide belt conveyors with stainless steel beams are specifically designed to fit into demanding primary and secondary packaging applications. It addresses important aspects of today's packing processes: easy to clean, smooth handling of products, safe for operators, robust design, long life, and easy to maintain with a low cost of ownership.