Total control in assembly line

One of the world's leading producers of pressure reducers for methane gas and LPG converting systems is an Italian manufacturer. They turned to FlexLink for a new assembly line.

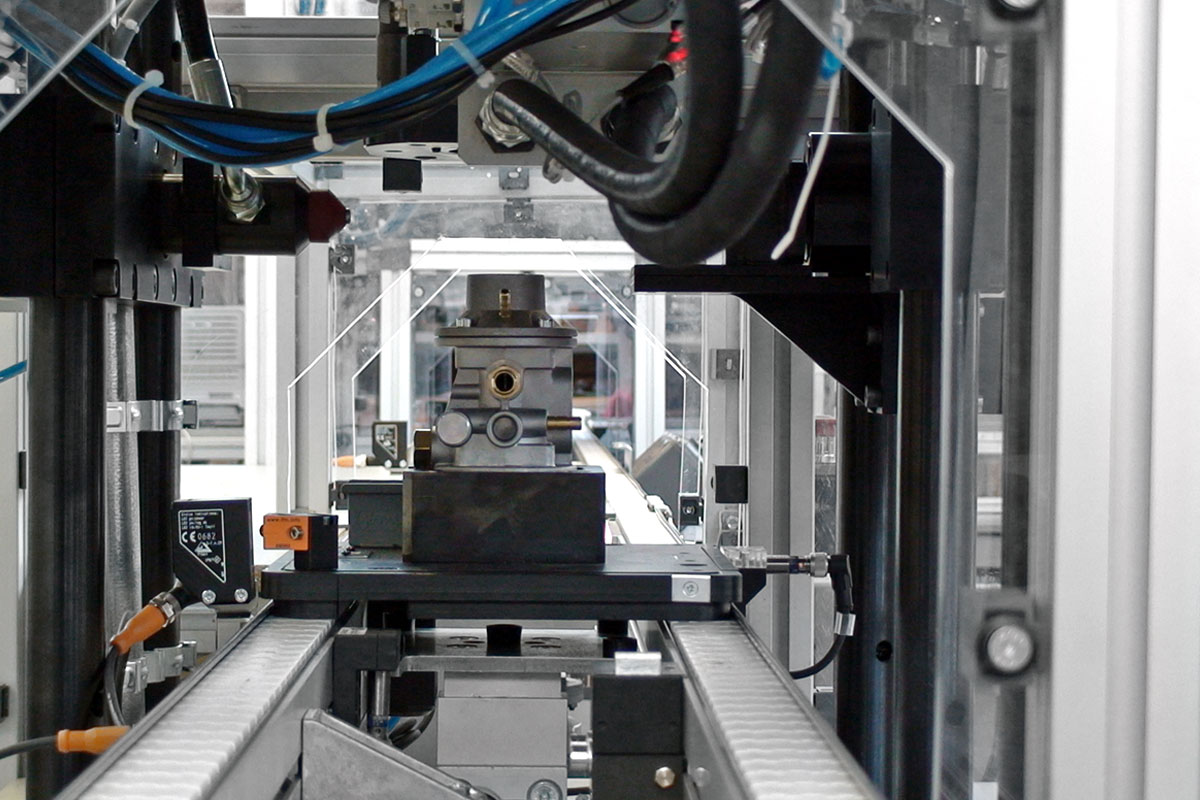

A semiautomatic line

The FlexLink hardware solution is an XT pallet loop extending over approximately 25 meters. This solution comprises manual and automatic stations with an electrical-pneumatic system, SCADA management, and a supervision system. The pallets are equipped with RFID memory tags. There are also two repair satellites. The automatic stations carry out screwing operations, testing, and calibration of pressure reducers. The manual stations were designed for optimum ergonomics and efficiency.

Process supervision system

This SCADA system can analyze a significant amount of data from the field, automatically checking for the presence of faults and then indicating this information to the operator using various interfaces (web, e-mail, sound and light signals, pagers, multiple types of portable terminals). The data is recorded and stored in a database for future processing. Consequently, a historical archive of the data can be used as a statistical basis by export to management applications or sent to various operational areas within the company. The system incorporates all the functions to guarantee the complete traceability of every single product.

Completely turn-key, including training

The FlexLink delivery was utterly turn-key. From hardware and software to control and training. For this project, FlexLink developed a detailed training plan for the personnel employed to run and maintain the system during the preparation phases at FlexLink and in the final stages of installation and commissioning at the user’s factory.

“As we were familiar with FlexLink’s working methods, we knew we were in safe hands: the required delivery times were met and FlexLink technicians were available at all times, both to analyze any production improvements with us and to offer help to our employees on the production lines” emphasizes the Industrialization Manager of the company.